Street and area lighting provides some great benefits to the users of the roads. It is not only essential to promote security in urban areas, improve safety for drivers, riders, and pedestrians, extend the usability of public spaces, but also plays a distinctive role in building stylish, unique and remarkable cities and landmarks.

Either selected from our standard range of street and area lighting poles, or customized to specific requirements, municipalities, developers, architects, and urban renewal professionals trust our capabilities in supplying high quality products complying to all international standards in place, reliable in performance and uniquely attractive in shapes and designs.

Decorative lighting poles are also offered in wide variety enabling urban developers to bring their choices to reality.

Main Features

Applicable Materials

Applicable Finishes

Compliance to International Standards:

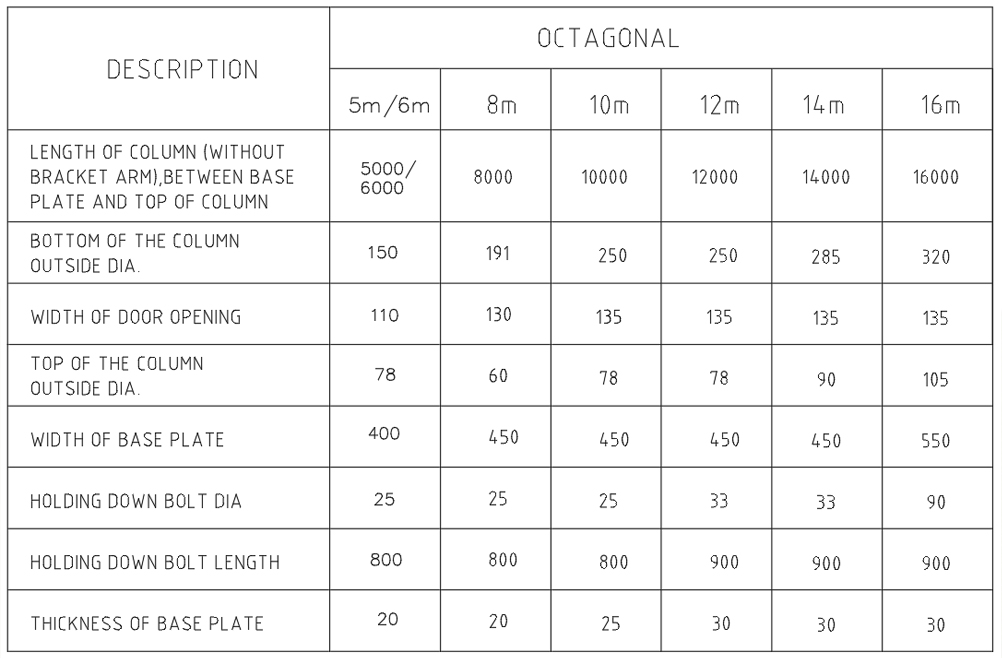

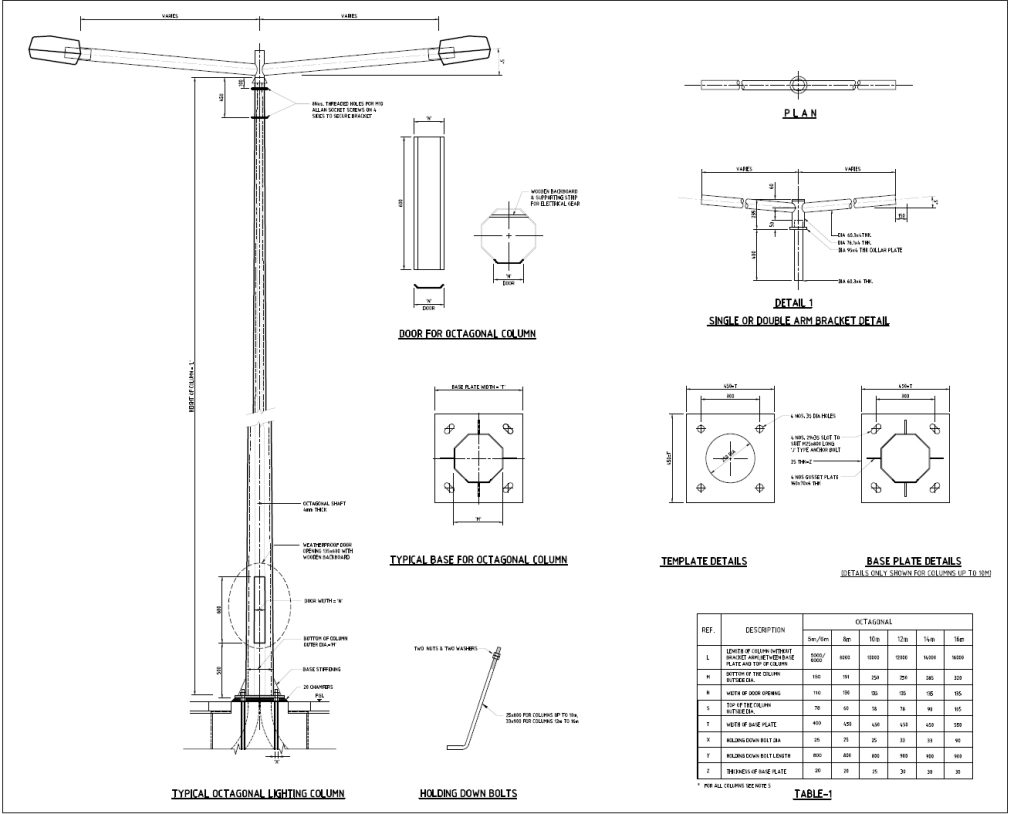

Technical Offerings:

Technical Drawing:

Copyright © 2024 COASTAL. All rights reserved.

Powered by 360 Bytes